The maximum floor screed thickness of a smoothing compound would usually be around 10mm.

Floor screed thickness uk.

Floor screed thickness find out the minimum and maxium depths for different screed products on various types of floor build up.

Liquid screed thickness with underfloor heating.

This is the most common and depending upon the site conditions most popular type of screed used.

Pye pw and harrison hw.

In this situation the liquid screed minimum thickness of 30mm is.

This is more if you want to install underfloor heating.

Semi dry floor screed what is it and what thickness is best.

Floors and flooring bre 2003.

There are many proprietary screeds on the market and information about these can be obtained from the manufacturer.

Traditional sand cement and anhydrite floor screeds dry at a rate of 1mm per day meaning months of drying before subsequent work can begin.

The readyscreed range are retarded for a specific time generally 12 hours and thus remain usable for one working day.

With ardex rapid drying floor screeds the area can be walked on in as little as 3 hours and floorcoverings can be installed in as little as 4 hours regardless of thickness.

Materials supplied in this way provide significant productivity benefits on site in addition to enhanced product quality.

When installing the floor you have to pay close attention to the screed thickness.

Find out more about our ready to use floor screed.

In this case the liquid screed minimum thickness is 40mm.

Ready to use floor screed.

There are proprietary screeds available that can be laid at thinner depths than conventional sand and cement screeds.

At uk screeds ltd we believe in perfection in all our floor screeding projects.

The thickness of floor screed unbonded is different.

There is one other variable which needs to be considered in liquid screed thickness and that is if the floor area is to have underfloor heating as part of the structure.

Issues to be taken into account include.

A floor screed is usually a cementitious material made from a 1 3 or 1 4 5 ratio of cement to sharp sand.

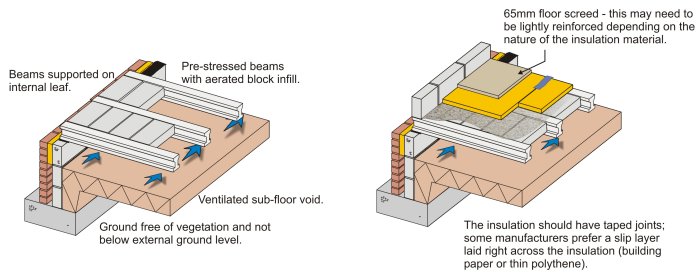

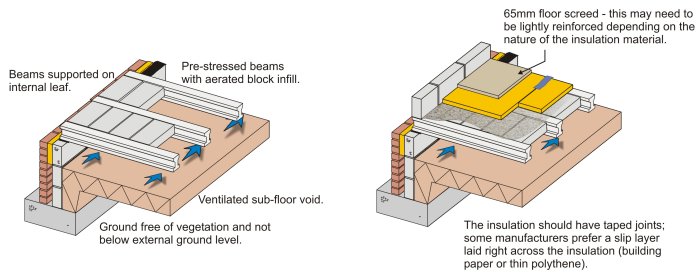

It may be applied onto either a solid in situ concrete ground floor slab or onto a precast concrete floor unit.

Traditional sand and cement would be the same.

Non structural floor screeds shall be adequate for the location and intended use and provide a suitable background for floor finishes.

This traditional screed mix is made up from sand and cement at a 1 3 5 ratio and is then spread onto the floor and allowed to solidify around the ufh pipes or cables.