Return the fluid release valve to its original position by turning it a half turn in a clockwise direction.

Floor jack oil level.

The funnel should prevent any unnecessary spills when refilling the oil.

I could see that the reservoir in my jack was nearly empty which explains its inability to lift a vehicle.

Use a small funnel or a large syringe to slowly add oil to the.

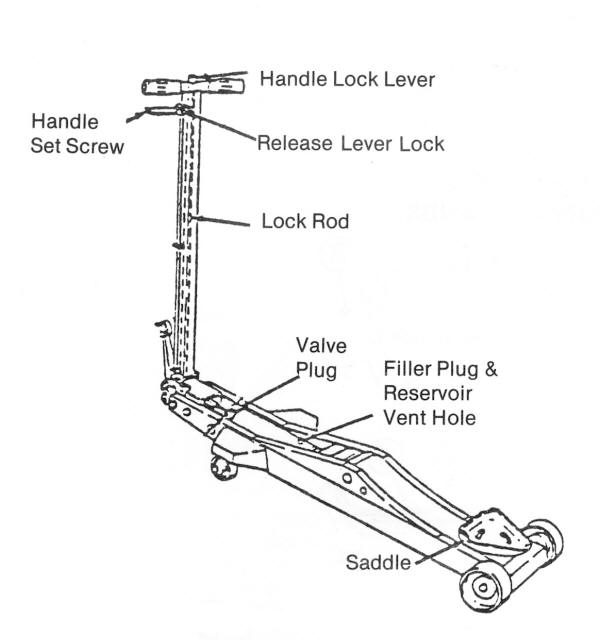

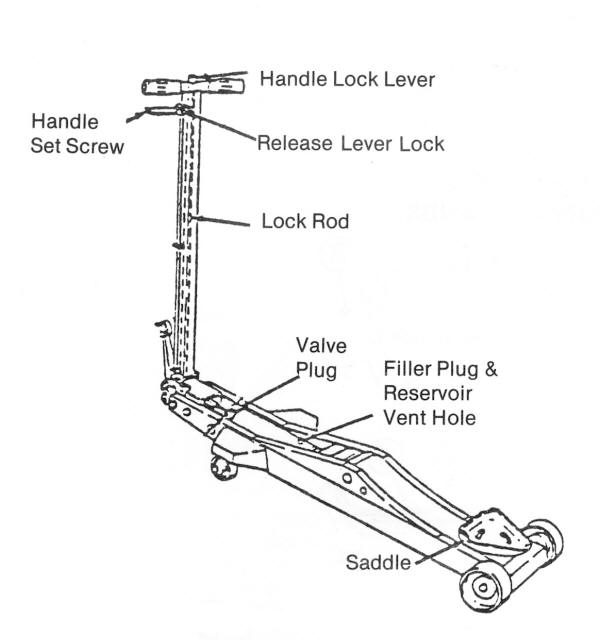

Put the jack in the down position by opening the release valve the valve that when opened allows oil to flow back into the main oil reservoir located at the bottom of the jack thus lowering the ram piston.

Filling jack oil reservoir.

If the oil is below this level high quality jack oil must be added.

To fix a floor jack that leaks down firstly check the reservoir from the level of oil in it.

Every floor jack will have the required level of the hydraulic fluid indicated.

Continue pressing until the jack is down to its lowest position.

Sometimes more oil could be the reason for leak down.

If the problem is not solved after these steps then the pressure valve needed to be repaired.

Only start pouring the oil when the funnel is in place.

The hydraulic jack oil should be visible 3 16 inch above the inner cylinder wall.

Press the jack downward.

Lift the arm and release it slowly it will lead to pushing the air out.

Use the jack handle to turn the valve a half turn in a counterclockwise direction.

Place your foot on the jack.

Look for any oil seepage around this valve.

Place the floor jack on a hard level surface.

Step 4 place the small end of a clean plastic funnel into the oil filler opening hole.

Hydraulic jack oil 8.